THV-10~100MDX Vickers Hardness Tester

The series of three objective automatic turret digital touch screen Vickers hardness tester is a:

Any three of the 5X, 10X, 20X, and 40X objective lenses are installed simultaneously

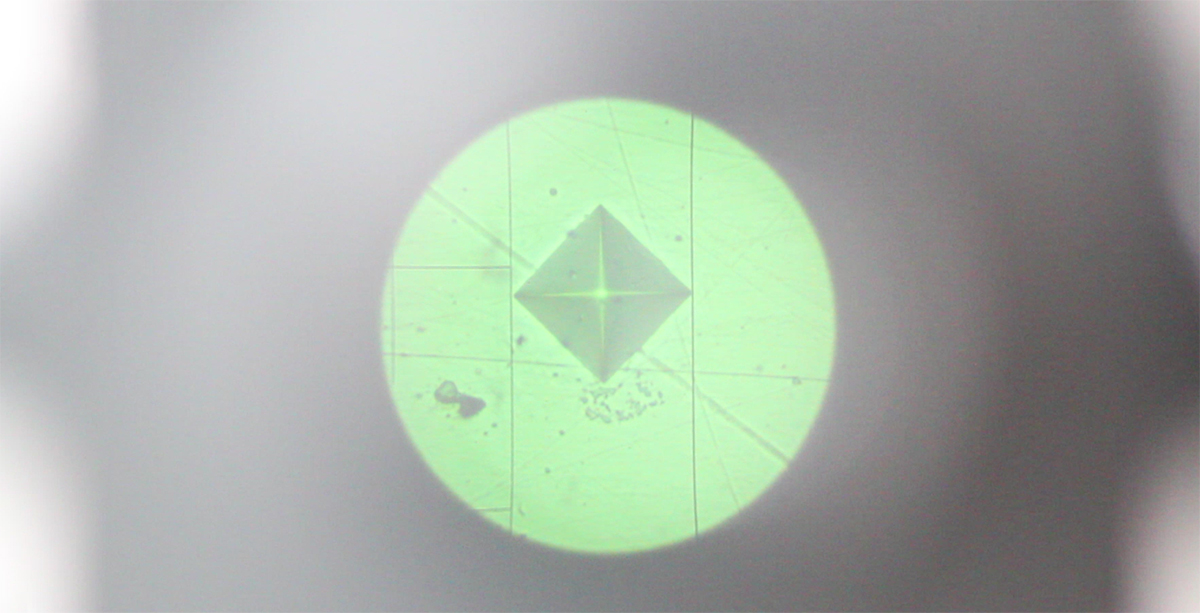

1.At the same time, any three objective lenses in 5X, 10X, 20X and 40X are installed to ensure that the indentation of different sizes can meet the standard size in the field of view. At the same time, a wide range of sample profile scanning can be carried out with low magnification.

2.All the three objective lenses can realize the measurement function

3.Level 11 test force, to meet all the test forces in the range of the standard

4.8 inch touch screen interface, easy to operate;

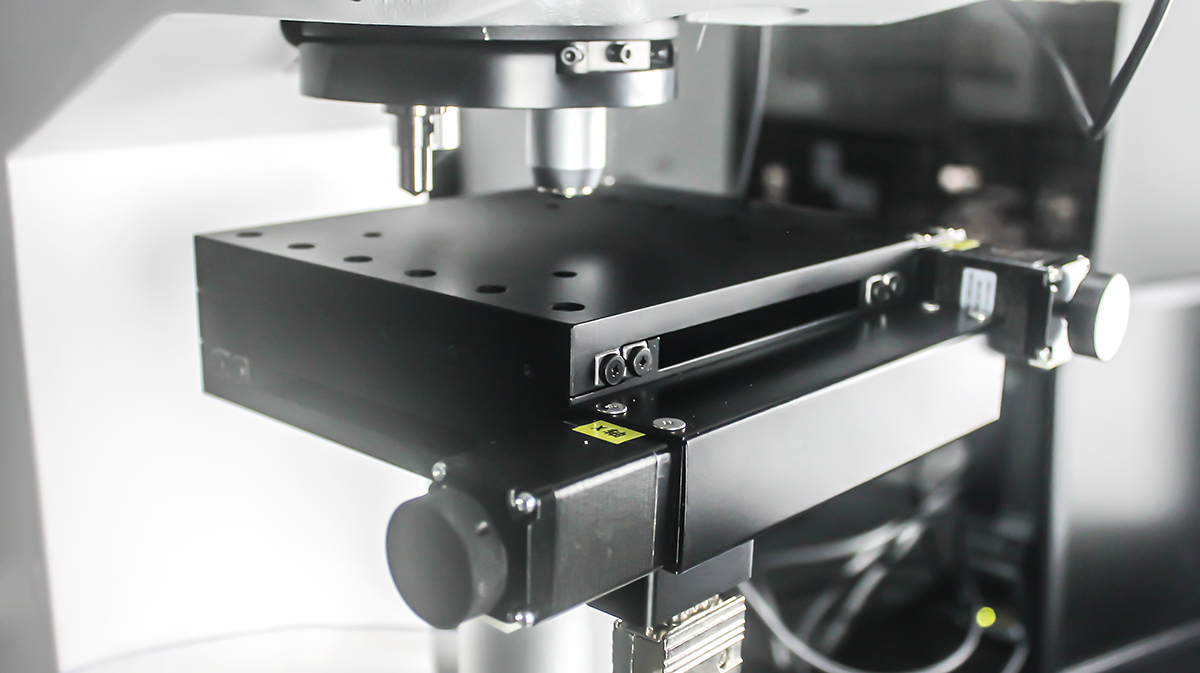

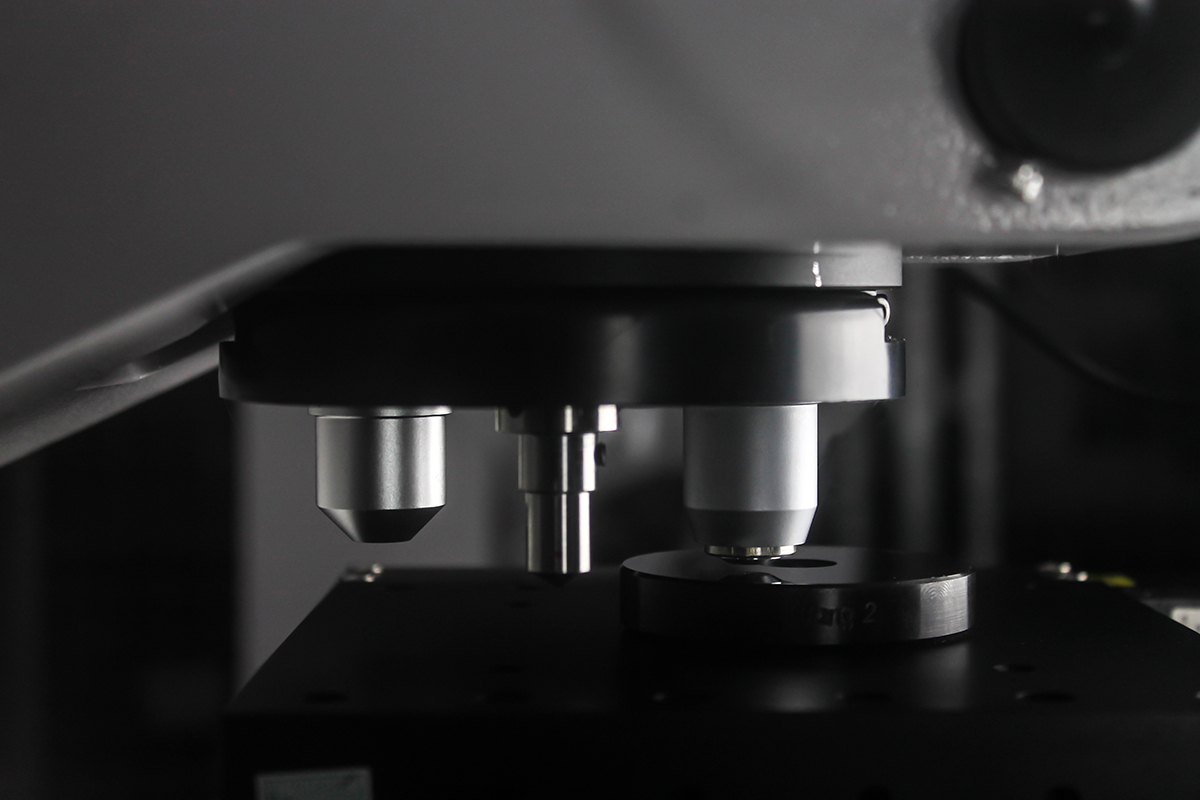

5.During the test, the pressure head and the objective lens automatically switch to each other, and the automatic positioning of the test point is accurate.

6.It can be calibrated according to the standard hardness block or length scale, and the hardness can be modified automatically according to the high, middle and low hardness values, and the hardness values are more accurate.

7.Various hardness values are converted to each other;

8.All test parameters and results are stored on USB flash disk in Excel format, which is convenient for data processing and test report output.

9.Test setting parameters are protected by password;

10.Light source using LED lamp, long life, no need to replace the bulb;

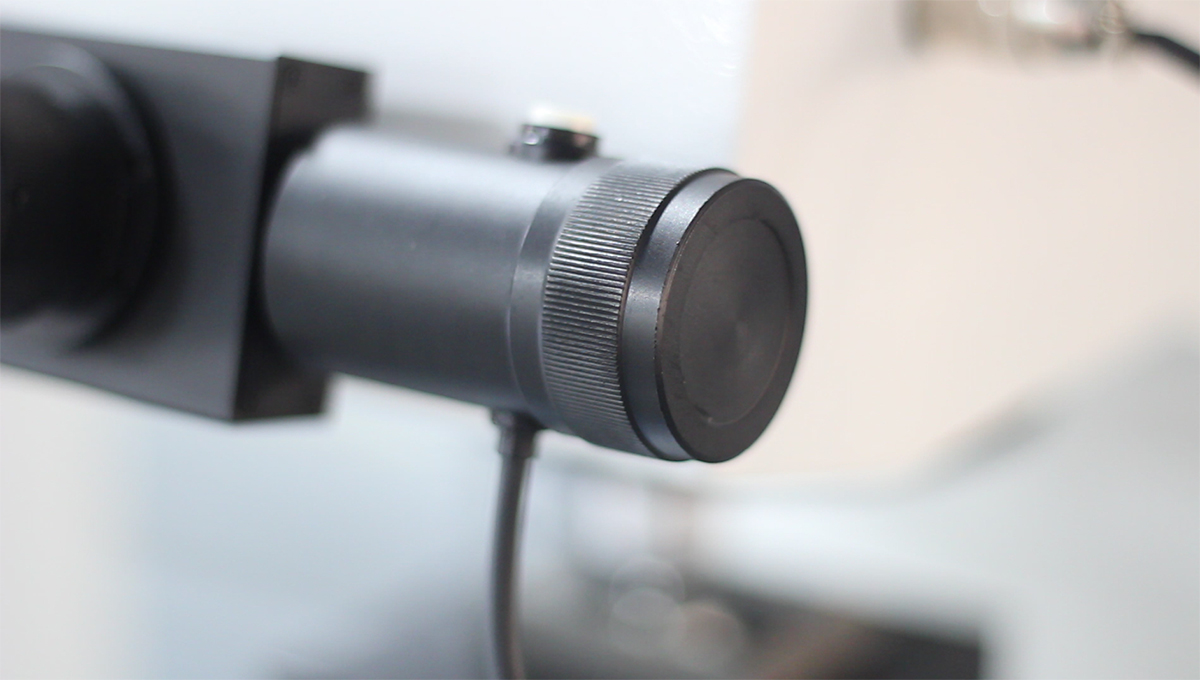

11.Built-in camera, clearer image (optional);

12.Chinese, English and other languages for choice;

13.With RS-232 interface, on-line with computer (optional)

Technical parameters:

| model | THV-10MDX-Q | THV-30MDX-Q | THV-50MDX-Q | THV-100MDX-Q |

| Test force | 0.3Kgf (2.94N), 0.5Kgf (4.90N), 1.0 Kgf(9.8N), 2.0Kgf(19.6N), 2.5Kgf(24.5N), 3.0Kgf(29.4N), 5.0Kgf(49.0N), 10.0Kgf(98.0N) | 0.5KGF (4.90N), 1.0KGF (9.8N), 2.0KGF (19.6N), 2.5KGF (24.5N), 3.0KGF (29.4N), 5.0KGF (49.0N), 10.0KGF (98.0N), 15.0KGF (147N), 20.0KGF (196N), 30.0KGF (294N)(optional 0.3KGF) | 1.0 Kgf(9.8N), 2.0Kgf(19.6N), 2.5Kgf(24.5N), 3.0Kgf(29.4N), 5.0Kgf(49.0N), 10.0Kgf(98.0N), 15.0Kgf(147N), 20.0Kgf(196N), 30.0 Kgf(294N), 40.0Kgf(392N), 50.0Kgf(490N)

(optional 0.5kgf) |

2.0kgf (19.6N), 3.0kgf (29.4N), 5.0kgf (49.0N), 10.0kgf (98.0N), 20.0kgf (196N), 30.0kgf (294N), 50.0kgf (490N), 60Kgf(588N), 80Kgf(784N), 100Kgf(980N)

(Force value can be customized) |

| Execution standard | GBT4340.1, GBT4340.2, ASTM_E92 | |||

| Conversion of hardness value | According to GB1172-99 and ASTM standards | |||

| Accuracy | JJG260-91, JIS B 7725, JIS B 7734, GB/ T3430.2-99

ASTM E-384, ISO 6507-2, ISO4546 |

|||

| Loading way | Automatically load/hold/unload | |||

| Automatic turret system | Automatic, manual

Object – indenter – objective switch rotation automatically The automatic turret provides a quick and simple sequence of operations without the need to manually rotate the tower to achieve automatic switching of the objective and indenter. The center of the objective lens and the center of the indenter have high precision and the error is less than 1 micron, which ensures the accurate pressure positioning of the sample and the center position of the objective lens can be adjusted. |

|||

| Minimum test unit | 0.01 mu m | |||

| Data output | LCD display readout, save to U disk in Excel format directly | |||

| Conversion scale | HRA, HRB, HRC, HRD, HRF, HV, HK, HBW, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T | |||

| Hardness test range | 8~2900HV | |||

| Test force application method | Automatic (loading, holding, unloading) | |||

| Measurement of the eyepiece | Electronic 10x (15X optional) | |||

| objective | Any three objective lenses in 5X, 10X, 20X, or 40X | |||

| Total magnification | 50X, 100X, 200X, 400X | |||

| Load holding time of test force | 1~99s | |||

| Maximum permissible specimen height | 180mm | |||

| Distance from center of indenter to outer wall | 160mm | |||

| size | 580*190*700mm | |||

| Weight | About 55 kg | |||

| Power | AC220V ± 5%, 50 to 60 hz | |||

Standard Accessory:

|

Item |

Quantity |

Item |

Quantity |

| DHV-1000-10X micrometer eyepiece |

1 |

Large, medium and V-shaped test bench |

Each one |

| Vickers hardness block |

2 |

Standby fuse (2A) |

2 |

| Power cable |

1 |

Dust bag |

1 |

| U disk |

1 |

Touch screen pen |

1 |

| Hexagon socket wrench (2.5mm) |

1 |

Adjust the foot level |

4 |

| Product qualification certificate, warranty card |

1 |

Instructions |

1 |