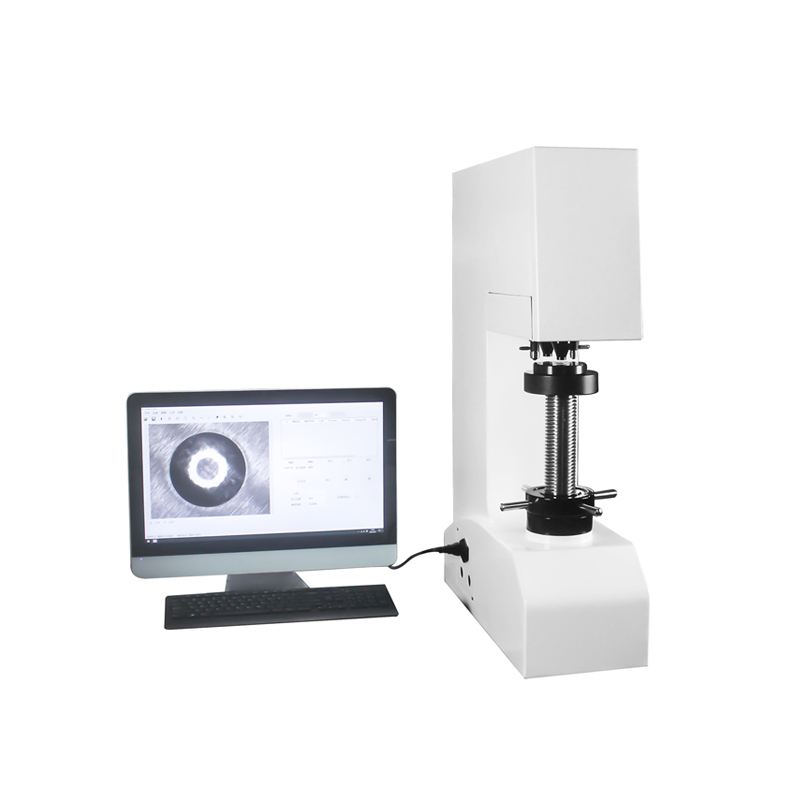

THB-3000MDP-Q Brinell Hardness Tester

1. The hardness tester is equipped with a computer and controlled by the computer;

2. Electronic and electric loading, high-precision sensor, unique closed-loop control system, 10 gears of force, and each gear of force is automatically compensated;

3. The test force can be corrected by software through standard dynamometer or standard block;

4. Automatic loading and unloading;

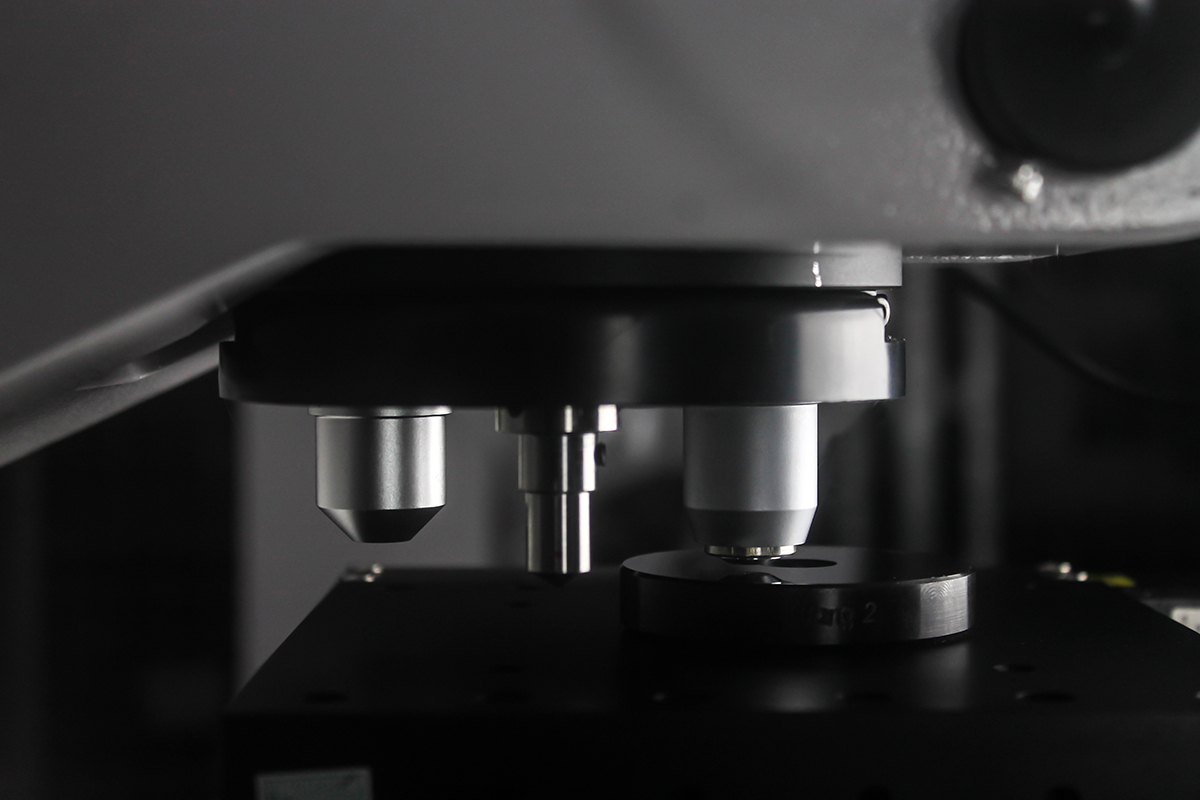

5. Automatic turret (except thb-3000dp). During the test, the indenter and objective lens automatically switch to each other, and the test points automatically and accurately locate, load and unload automatically;

6. The host machine is equipped with double indenters (two optional for 10, 5, 2.5mm and 1mm) and double objective lenses (double magnification 20x / 40x). For large and small Brinell indentations, there is no need to replace the indenter and measuring objective lens (thb-3000mdp-q)

7. The sample (Z-axis) rises and falls automatically to achieve one key hardness value (thb-3000mdp-z type);

8. 5 megapixel industrial digital camera is adopted, with clear image;

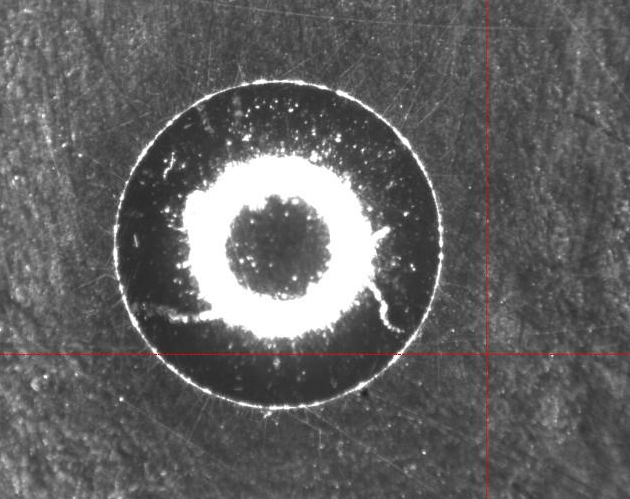

9. The computer automatically measures the indentation size and hardness value;

10. The hardness value correction can be calibrated according to the standard hardness block or length scale;

11. Automatic Brinell Rockwell Vickers hardness conversion according to GB / ASTM standards;

12. Powerful database function, permanent storage and convenient query;

13. The interface and functions can be customized, such as external QR code scanning and other functions (options);

14. Automatically generate user-defined inspection report. Automatically record measurement data and output word report according to user customization; Automatically record the measurement data, and save all data in Excel format.

Technical parameters:

| model | THB-3000DP | THB-3000MDP | THB-3000MDP-Q | THB-3000MDP-Z |

| The name of the | Computer Brinell hardness tester | Computer automatically turret Brinell hardness tester | Computer automatic turret double indenters, double objective Brinell hardness tester | Full automatic Brinell hardness tester |

| The computer |

All-in-one computer or industrial control touch-screen computer (optional) |

|||

| Automatic turntable |

– |

Y |

||

| Double head |

– |

Y |

||

| Double objective |

– |

Y |

||

| Sample (Z-axis) automatically rises and falls |

– |

Y |

||

| Brinell hardness scale | HBW2.5/62.5, HBW2.5/187.5, HBW5/62.5, HBW5/125, HBW5/250, HBW5/750, HBW10/100, HBW10/250, HBW10/500, HBW10/1000, HBW10/1500, HBW10/3000 | |||

| Test force (Kgf) | 62.5kgf(612.9N), 100kgf(980.7N), 125kgf(1226N),

187.5KGF (1839N), 250KGF (2452N), 500KGF (4903N), 750KGF (7355N) 1000KGF (9807N), 1500KGF (14710N), 3000KGF (29420N) |

|||

| Conform to the standard | BSEN 6506, ISO 6506, ASTM E10, GB/T231 | |||

| Accuracy of test force | 62.5 ~ 250kgf≤1% 500 ~ 3000kgf≤0.5% | |||

| Resolution of measuring device | 0.1 um | |||

| Hardness resolution | 0.1 HBW | |||

| Bao load time | 0 ~ 99 s | |||

| Maximum specimen height | 200mm(customizable) | |||

| Distance between head and wall | 155mm(customizable) | |||

| Computer | 19 inch. Win10 operating system | |||

| camera | 500 pixels | |||

| The weight of the | 110kg | |||

| The power supply | AC220 + 5%, 50 ~ 60 hz | |||

Standard Accessory:

|

Serial number |

Item |

Quantity |

|

1 |

All-in-one computer or industrial control touch-screen computer (optional) |

1 |

|

2 |

camera |

1 |

|

3 |

Camera interface |

1 |

|

4 |

Large, medium and V-shaped test tables |

Each 1 |

|

5 |

Cemented Carbide Ball Indenter (Diameter 2.5, 5, 10mm) |

Total 3 |

|

6 |

Standard Hardness Block (HBW10/3000, HBW10/1000,HBW2.5/187.5) |

Total 3 |

|

7 |

Dust bag |

1 |

|

8 |

Standby fuse (2A) |

2 |

|

9 |

The power cord |

1 |

|

10 |

Product qualification certificate, warranty card |

1 |